Linear Stepper Motors in Automotive Camera and Radar Alignment: Ensuring Optimal Sensor Accuracy

Advanced driver-assistance systems (ADAS) and autonomous driving technologies are increasingly prevalent, driven by advancements in vehicle technology. For these systems to give a thorough picture of the vehicle’s surroundings, a variety of sensors, such as cameras and radar, are extensively relied upon. For vehicles to operate safely and effectively, these sensors’ accuracy and precision must be guaranteed. This is where linear stepper motors play a vital role.

Linear stepper motors are now being widely used in automotive applications, particularly in the alignment and adjustment of cameras and radar sensors. In this article, we’ll delve into the significance of linear stepper motors in sensor alignment and explore how they contribute to enhancing automotive safety. We’ll also touch upon the complementary role of worm gear motor manufacturers in supporting sensor alignment applications.

The Importance of Sensor Accuracy in ADAS and Autonomous Driving

In today’s automotive landscape, cameras and radar sensors are at the core of many advanced features. From lane-keeping assistance and adaptive cruise control to collision avoidance and autonomous driving, these sensors provide real-time information about the vehicle’s environment. Even a slight misalignment of a sensor can lead to significant inaccuracies, compromising the effectiveness of these systems.

Cameras and radar sensors must be aligned with millimeter precision to ensure that their field of vision and detection range are optimized. Misaligned sensors can result in false readings, limited detection range, and compromised safety. Thus, achieving precise alignment is paramount for delivering the promised benefits of ADAS and autonomous driving systems.

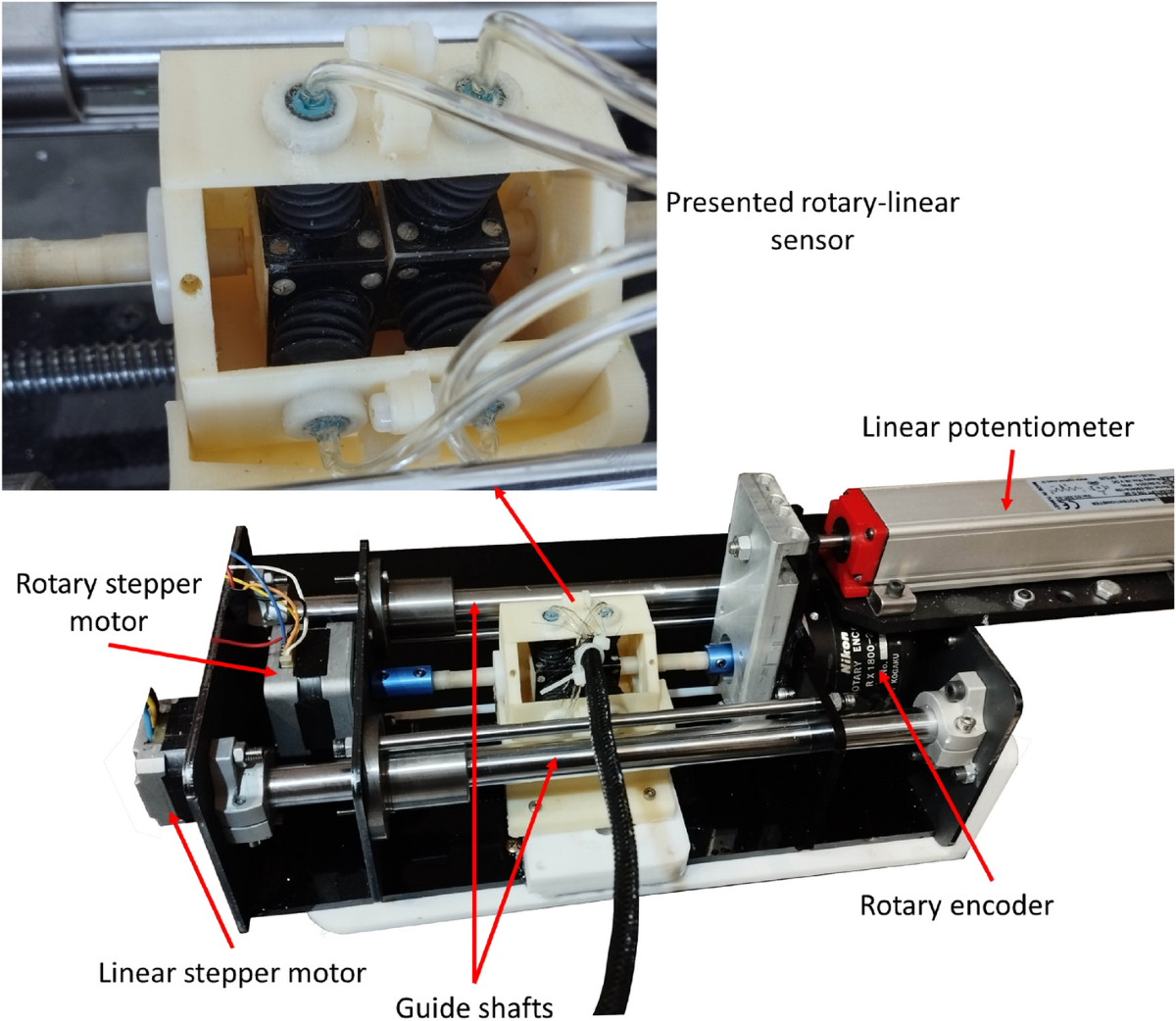

The Role of Linear Stepper Motors in Sensor Alignment

Linear stepper motors are known for their ability to provide precise, incremental movement, making them ideal for fine-tuning sensor positions. These motors provide the regulated movement required to accomplish precise sensor alignment by converting electrical pulses into linear motion. This precise motion allows automotive engineers to make incremental adjustments to the position of cameras and radar sensors, ensuring that they are perfectly aligned with the vehicle’s axis.

Key applications of linear stepper motors in sensor alignment include:

Camera Alignment

For functions like parking assistance, lane departure warning, and pedestrian identification, cameras are essential. Linear stepper motors enable the fine adjustment of camera angles, ensuring that the camera’s field of view is accurate. For example, during the calibration process, linear stepper motors can adjust the camera’s vertical and horizontal position to achieve the desired alignment with respect to the road and vehicle.

Radar Sensor Adjustment

Radar sensors are essential for detecting objects, measuring distances, and enabling adaptive cruise control. Linear stepper motors allow radar sensors to be precisely positioned during assembly and calibration, ensuring that the sensor’s detection range and coverage are optimized. These adjustments can be made both during manufacturing and in service centers if re-calibration is required.

Dynamic Sensor Adjustment

With the advent of smart sensor technologies, some vehicles now feature dynamic alignment capabilities. This involves the real-time adjustment of sensors based on changing driving conditions or load variations. Because linear stepper motors can move objects precisely and smoothly, they are an excellent choice for this kind of work. This adaptability ensures that the sensors remain accurately aligned in varying conditions.

Why Linear Stepper Motors?

The following benefits of using linear stepper motors make them perfect for automobile sensor alignment applications:

High Precision and Accuracy

Linear stepper motors provide precise control over linear motion, allowing for incremental adjustments in micrometer ranges. This level of accuracy is essential for aligning sensors, where even minor deviations can affect sensor readings and vehicle safety.

Compact Design

Because of their small size, linear stepper motors may be installed in confined areas within sensor modules in vehicles. This compactness makes it easier for automotive engineers to integrate them into complex sensor systems without adding bulk or weight.

Low Power Consumption

Linear stepper motors consume minimal power, which is beneficial in automotive applications where energy efficiency is a priority. Their ability to maintain positions without continuous power supply makes them energy-efficient solutions for sensor alignment tasks.

The Role of Worm Gear Motors in Sensor Alignment

While linear stepper motors provide the fine-tuned motion required for sensor alignment, worm gear motor manufacturers play a complementary role in providing the necessary torque and stability. Worm gear motors are well-known for their high torque output and capacity for self-locking, which makes them perfect for load-handling and steady positioning applications.

For example, in the case of radar sensors, which are often larger and heavier than cameras, worm gear motors provide the necessary torque to hold the sensor in place while linear stepper motors handle fine adjustments. The combination of linear stepper motors and worm gear motors enables automotive engineers to achieve optimal sensor positioning with both precision and stability.

Enhancing Sensor Accuracy with Automation

The automation of sensor alignment processes using linear stepper motors has significantly improved the consistency and reliability of sensor positioning in modern vehicles. By integrating linear stepper motors with automated calibration systems, manufacturers can achieve high levels of accuracy in a fraction of the time compared to manual adjustments.

This automation not only enhances the alignment of individual sensors but also improves the overall calibration of sensor arrays. Vehicles are better equipped to comprehend their environment when they are precisely positioned and automatically aligned, which makes ADAS and autonomous driving systems safer and more dependable.

Future Trends in Sensor Alignment

As the demand for autonomous vehicles and ADAS continues to grow, the role of linear stepper motor manufacturers will become increasingly significant. It is anticipated that developments in sensor technology and alignment procedures will propel future improvements in vehicle performance and safety. Linear stepper motors, with their ability to provide precise motion and compact design, will remain at the forefront of these innovations.

In addition, worm gear motor manufacturers will continue to play a crucial role in providing the torque and stability needed for sensor modules, especially in applications that require heavy or dynamically adjustable sensors. The collaboration between linear stepper motor and worm gear motor manufacturers will enable the development of more advanced sensor alignment systems, ensuring that future vehicles are equipped with the highest levels of accuracy and safety.

Conclusion

Linear stepper motors are revolutionizing the alignment of cameras and radar sensors in modern vehicles, ensuring that these critical components are precisely positioned for optimal accuracy. Their tiny size, low power consumption, and ability to create precisely regulated motion make them ideal for use in automotive applications.