Electric Motor Cores: A Key Factor in Reducing Energy Loss in Electric Vehicles

As electric vehicles (EVs) become more mainstream, manufacturers are constantly seeking ways to increase their efficiency. Among the many components that impact overall performance, the electric motor core plays a pivotal role in reducing energy loss, boosting efficiency, and extending vehicle range. This essential component is at the heart of electric motors, where its design and material choices are key to unlocking the full potential of EVs.

The Function of the Electric Motor Core

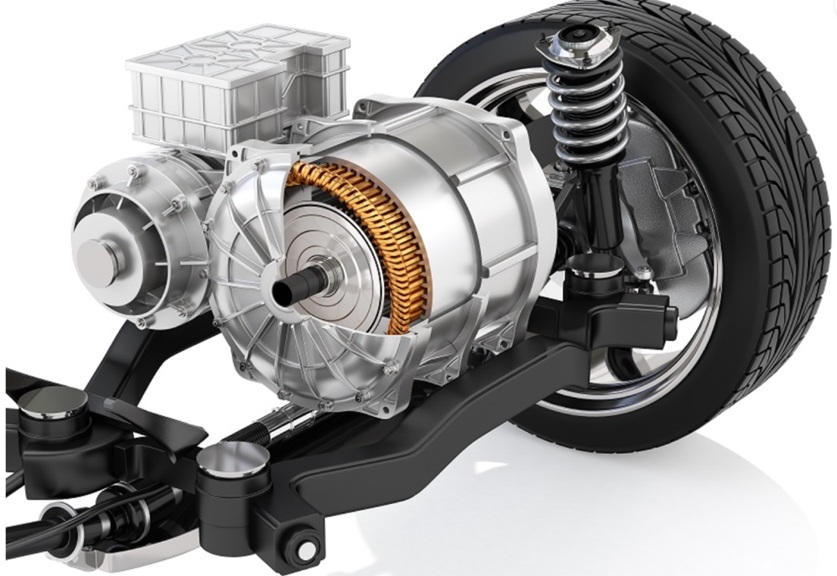

The stator core and the rotor core are the two main parts of the electric motor core.The stator core is the stationary part that generates the magnetic field, while the rotor core rotates within this field to produce mechanical power. Together, they form the magnetic circuit that drives the motor’s motion. To reduce energy losses from eddy currents, the stator and rotor cores are usually constructed from electrical steel sheets that have been laminated and stacked together. These currents have the potential to produce undesired heat, which lowers the motor’s overall performance and efficiency.

For electric vehicles, minimizing these losses is crucial for improving performance. The more efficiently the stator and rotor cores work, the less energy is wasted in the form of heat. This translates directly into longer driving ranges, less strain on the battery, and overall better performance—critical factors in the competitive EV market.

Materials and Design: Reducing Energy Loss

The electric motor core’s composition has a big impact on how efficient it is. Traditional motor cores use silicon steel, which helps reduce losses and increase conductivity. However, newer materials like amorphous steel and advanced magnetic alloys are gaining attention due to their superior properties. These materials can further reduce energy loss, improve performance, and allow the motor to operate at higher speeds without overheating.

The core’s design also matters. Innovations such as thinner laminations or improved stacking techniques minimize the energy lost during operation. With thinner laminations, the path for eddy currents is reduced, leading to fewer losses. More advanced designs involve multi-layer laminations or even hybrid cores that combine different materials for optimal performance. These innovations are essential as the push for higher efficiency continues in the EV industry.

The Impact on EV Efficiency and Range

In electric vehicles, motor efficiency directly affects energy consumption. A highly efficient motor core means that more of the power stored in the battery is converted into motion, and less is lost as heat. This has a significant impact on the vehicle’s range, making the difference between being able to travel an extra 20 or 50 miles on a single charge. As consumer demand for longer ranges continues to grow, optimizing motor cores has become a top priority for EV manufacturers.

In addition to range, reducing energy loss in the motor core also reduces the need for large, heavy batteries. Smaller, more efficient motor cores mean that manufacturers can design lighter, more compact battery packs, which further contribute to vehicle performance, agility, and efficiency.

Innovations in Motor Core Technology

The development of electric motor cores is continuously evolving. One major area of innovation is the use of permanent magnets in the core, which can generate stronger magnetic fields without consuming additional power. This design eliminates some of the energy losses seen in traditional cores, enhancing motor efficiency. Researchers are also exploring advanced cooling systems that maintain optimal core temperatures, ensuring the motor performs efficiently even under heavy loads.

In addition, manufacturers are investing in advanced manufacturing techniques to improve motor core production. Precision manufacturing methods help to create more uniform cores, further reducing energy loss and increasing the overall performance of the motor. By employing cutting-edge technology, motor cores are becoming more reliable, more efficient, and better suited for the demands of modern electric vehicles.

Conclusion

The electric motor core is an essential component in reducing energy loss and maximizing the performance of electric vehicles. Through material improvements, design innovations, and advanced manufacturing techniques, manufacturers are making significant strides in improving motor efficiency.

As the demand for electric vehicles continues to rise, optimizing motor cores will play a critical role in shaping the future of sustainable transportation. By prioritizing energy-efficient designs, manufacturers can contribute to creating more reliable, efficient, and high-performing electric vehicles.